ACQUIRED 1987

ACQUIRED 1987

EMPLOYEES 300+

HEADQUARTERS Piqua, Ohio

WEBSITE HartzellProp.com

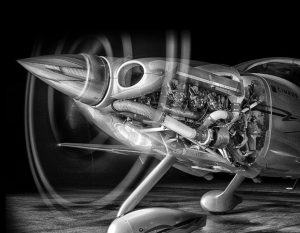

Hartzell Propeller is the leading manufacturer of aircraft propeller systems in the world and serves the general aviation industry globally. Founded in 1917, the company has been owned by the Browns since 1987 when it was acquired from TRW. Hartzell is headquartered in Piqua, Ohio, and employs 300+ people. Hartzell designs and builds constant-speed variable pitch propellers for general aviation applications – both piston engine and turboprop. Aircraft propellers are highly engineered, flight-critical components tailored to individual aircraft. Engineering and quality assurance skills are crucial to the business as are best-of-class manufacturing capabilities. Some of the capabilities of the business include:

ACQUIRED 2010

ACQUIRED 2010

EMPLOYEES 120

HEADQUARTERS Montgomery, Alabama

WEBSITE Hartzell.aero

Hartzell Engine Technologies was formed in 2010 after the acquisition of the assets of Kelly Aerospace Energy Systems, LLC. and employs 120 people. Hartzell Engine Technologies product lines include turbocharger systems, alternators, starters, Janitrol Heaters, South Wind heaters, fuel pumps, voltage regulators and a large range of other electrical components. These products primarily serve piston-engine general aviation, military aircraft, as well as piston and turbine engine helicopters. Some of the capabilities of the organization include:

ACQUIRED 2019

EMPLOYEES 90

LOCATION Eagan, Minnesota

WEBSITE awi-ami.com and aerospacemanufacturing.com

AWI’s specializes in welding, bending and fabricating sheet metal and tubing and manufactures, repairs and overhaul piston aircraft exhaust and engine mounts. AMI specializes in machining and welding with a focus on bending and welding tube assemblies for jet engines and airframes and metal details for AWI’s exhaust and engine mount business. Some capabilities of the business include:

ACQUIRED 2019

EMPLOYEES 50

HEADQUARTERS Tulsa, Oklahoma

WEBSITE qaa.com

Quality Aircraft Accessories is a FAA Part 145 Class 1 and Class 2 Repair Station with locations in Tulsa, Oklahoma and Ft. Lauderdale, Florida with the in-house ability to overhaul most engine and airframe accessories. QAA is also a stocking aircraft distributor for many general aviation accessory manufacturer, including Champion, Dukes, Weldon Aerospace, Hartzell Engine Technologies, Precision Airmotive, Sky-Tec, Marvel Schebler, Tempest,Ametek/Drake Air, Lamar, Rapco, Inc, Plane-Power, Aerospace Turbine Rotables and Kelly Aerospace. Some of the capabilities of the business include:

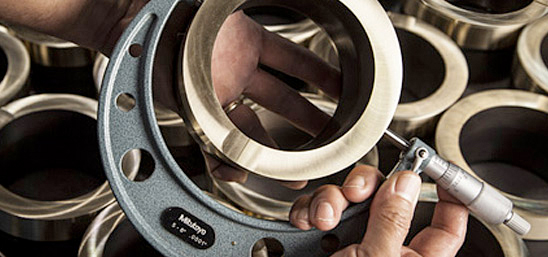

ACQUIRED 2009 EMPLOYEES 170 HEADQUARTERS Denton, Texas Mayday provides the global aerospace community with close tolerance machined components. The company has long experience producing bushings, sleeves, pins and other turned components many of which include complex milled features. Founded in 1966, Mayday serves the market with components that can be found on most of the world’s commercial aircraft and many tactical and transport military platforms. The company currently serves about 800 customers in 16 countries, including the world’s most recognized prime contractors and all of their associated supply chain participants. Mayday is a recognized and preferred supplier to Boeing, Bell Helicopter, Goodrich, Messier-Dowty, Heroux Devtek, GE and many others. Unique capabilities of the organization include:

ACQUIRED 2009 EMPLOYEES 170 HEADQUARTERS Denton, Texas Mayday provides the global aerospace community with close tolerance machined components. The company has long experience producing bushings, sleeves, pins and other turned components many of which include complex milled features. Founded in 1966, Mayday serves the market with components that can be found on most of the world’s commercial aircraft and many tactical and transport military platforms. The company currently serves about 800 customers in 16 countries, including the world’s most recognized prime contractors and all of their associated supply chain participants. Mayday is a recognized and preferred supplier to Boeing, Bell Helicopter, Goodrich, Messier-Dowty, Heroux Devtek, GE and many others. Unique capabilities of the organization include:

ACQUIRED 2009 EMPLOYEES 90 HEADQUARTERS Denton, Texas Hi-Tech Metal Finishing is a metal processor providing support for aerospace components that are part of almost every commercial and military aircraft flying today. The company is approved by most aerospace prime contractors to do anodizing, cadmium plate, chem film (alodine), liquid penetrant inspection, magnetic particle inspection, passivation and prime / paint. Unique capabilities of the organization include:

ACQUIRED 2009 EMPLOYEES 90 HEADQUARTERS Denton, Texas Hi-Tech Metal Finishing is a metal processor providing support for aerospace components that are part of almost every commercial and military aircraft flying today. The company is approved by most aerospace prime contractors to do anodizing, cadmium plate, chem film (alodine), liquid penetrant inspection, magnetic particle inspection, passivation and prime / paint. Unique capabilities of the organization include:

ACQUIRED 2004 EMPLOYEES 244 HEADQUARTERS Valencia, CA Hartzell Aerospace was formed out of the combination of Industrial Tub Corp, Electrofilm Manufacturing Company and AcousticFab and has two manufacturing sites in California with 244 employees. They are a leader in engineering, qualification, testing and manufacturing custom designed aerospace products used in environmental control subsystems (“ECS”). Each custom designed ECS includes noise attenuation, heaters, freeze protection, ice protection, composite components and other ancillary parts. These products serve the commercial aerospace industry and supply the leading OEMs and Tier 1 suppliers such as United Technologies, Boeing, Zodiac Aerospace, Honeywell, Bell Helicpoter & Embraer. Unique Capabilities of the organization